- Home > Blog >

Gas Type Wafer Biscuits Plant Working Process

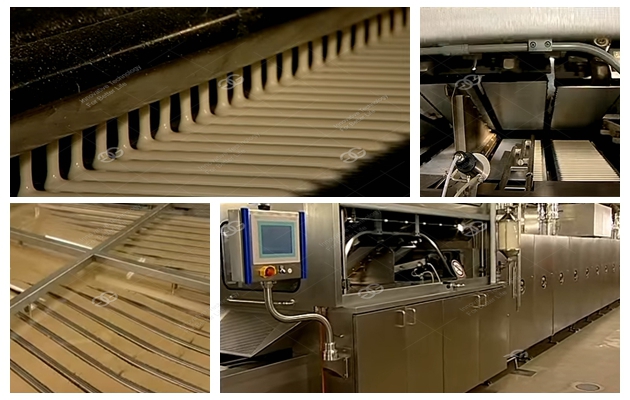

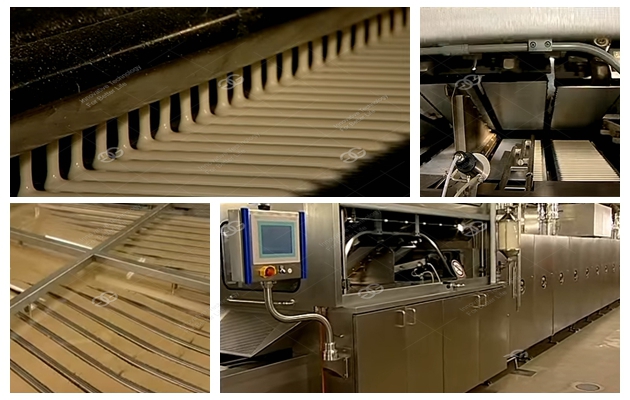

The wafer biscuit making line can be divided into two different heating ways. One is gas hating way, another is electric heating way. The wafer biscuit making process is very computerized, every part is controlled by computer. In the whole gas heating way making process, the baking oven is very important, it has gas in the bottom of the oven, it will erupted baked wafe sheets. There are different cappcity and different heating ways can be choosed.

Fistly, the flour wihch has been mixing in the blending machine will put into the wafer sheet baking oven, about 2 to 3 minutes. Then wafer sheets will formed, and transfered with the conveyor belts to the cooling machine.

Secondly, the wafer picking machine will check these wafer sheets, if they have some wafer sheets are broken, thees wafer sheets will be picked up. The another wafer sheets will send to the cream spreading machine. The cream's color and taste is according this machine. The thickness and layers of the wafers can be changed though this machine.

Thirdly, in order to reduce wafer deformation and cream overflow, the cooling cabinet is best choice for businessmen in their making process. This machine can cooling wafers and stereotypes them.

Finally, these wafer sheets is ok to cut into pieces. The wafer biscuit's size can be changed by the cutting blade. And packing wafer biscuits just need the pillow packing machine is ok.

This the sample wafer biscuit making process.